How Do I Calculate How Much Ballast I Need Add To A Rov To Reach Neutral Buoyancy?

Build Your Ain Remotely Operated Underwater Vehicle — Part 1: Construction

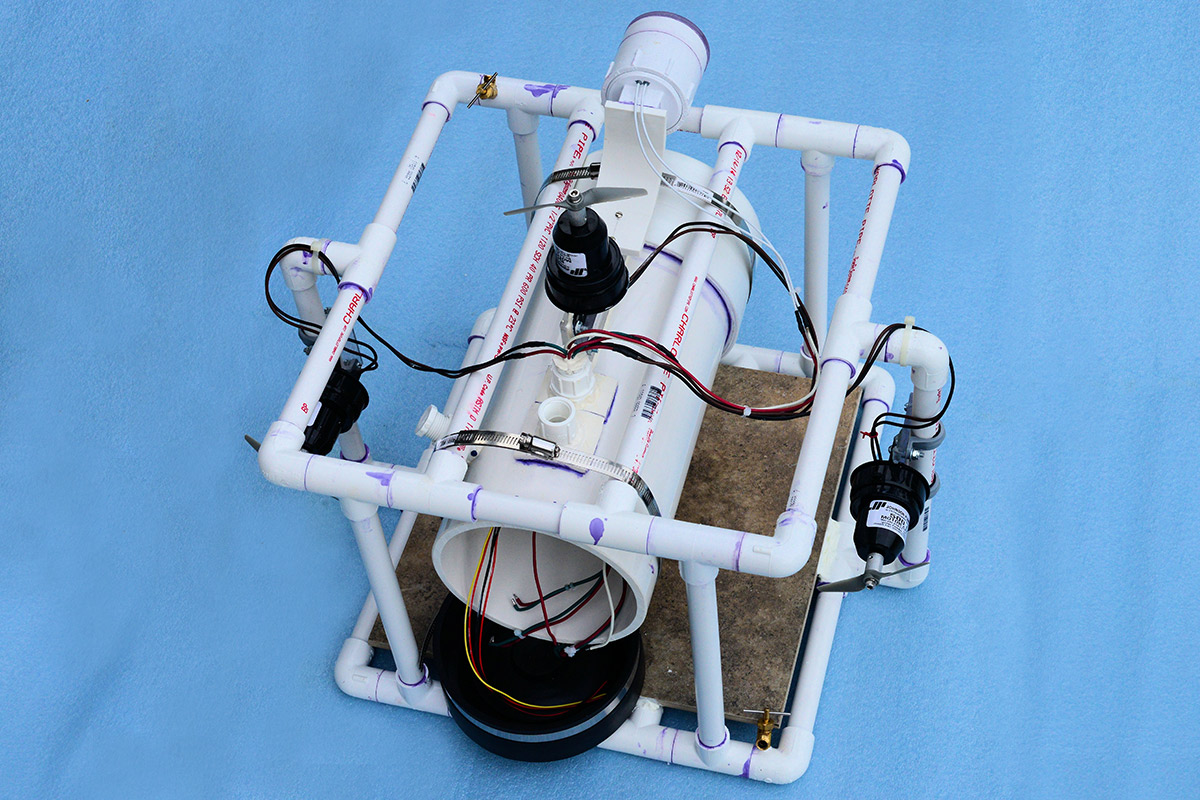

Having lived near the water most of my life and with manatees showing up regularly in the water nearby where we live in Florida, I developed an interest in having an ROV (Remotely Operated Vehicle) to video sea life underwater. Purchasing an ROV can be expensive, so after several prototypes, I successfully constructed an ROV from easily acquired parts that can be assembled with bones tools. Calling this project my ROV Manatee seemed advisable.

The Challenges of and Solutions for Watertight Builds

Engineering your own ROV has construction challenges beyond designing and building the necessary electronics. The electronics bundle for the design is housed within a half dozen inch PVC pipe, with a tether cablevision running topside to a joystick steering mechanism. The tether is Cat5 cable and must enter the PVC pipe through a watertight seal. Additionally, the wires from the motors and optional calorie-free must also feed into the PVC pipe to connect to the motor drivers.

The integrity of these watertight connections is an absolute must as whatsoever h2o leak can be catastrophic to the electronics inside. My elementary solution was to drill holes in the six inch PVC and so use marine epoxy to glue a 1/2 inch PVC coupling that is threaded on the inside. The wires are and so pulled through a pigsty drilled in a 1/ii inch PVC threaded plug, after coating each wire with marine epoxy. The entire plug is then filled with additional marine epoxy. It is of import that each wire going through the hole in the PVC plug take an epoxy coat effectually it earlier bundling them and passing them through the hole. The PVC plug is wrapped with Teflon™ tape and screwed tightly into the coupling.

A 2nd challenge is achieving neutral buoyancy for the ROV, as well as a counterbalanced trim. The half-dozen inch PVC tube and the 1/2 inch PVC frame human activity as floats, while the full weight of the ROV acts to sink it. These two must be balanced so that the ROV attains neutral buoyancy, where information technology simply hovers and does not sink or float to the top. This ROV needed additional weight.

After struggling with several ideas, the solution was a fourteen inch square of ceramic tile, cemented to the bottom of the frame with bathtub caulk along with several smaller iv inch square pieces. To fine-tune the buoyancy, a pocket-size petcock was added at the peak and bottom of the frame. With the ROV just barely floating, these petcocks can be opened allowing a little h2o to enter the frame and adding weight. Adjusting how much water is in the frame can achieve well-nigh neutral buoyancy.

The trim of the ROV must be level; the position of the ballast is used to accomplish this. The height of the left and correct motors must also match the vertical centre of mass of the ROV. This allows the motors to push the ROV in a level management. For example, if the motors are mounted too low, their thrust would tip the bottom of the ROV forward causing the ROV to ascend.

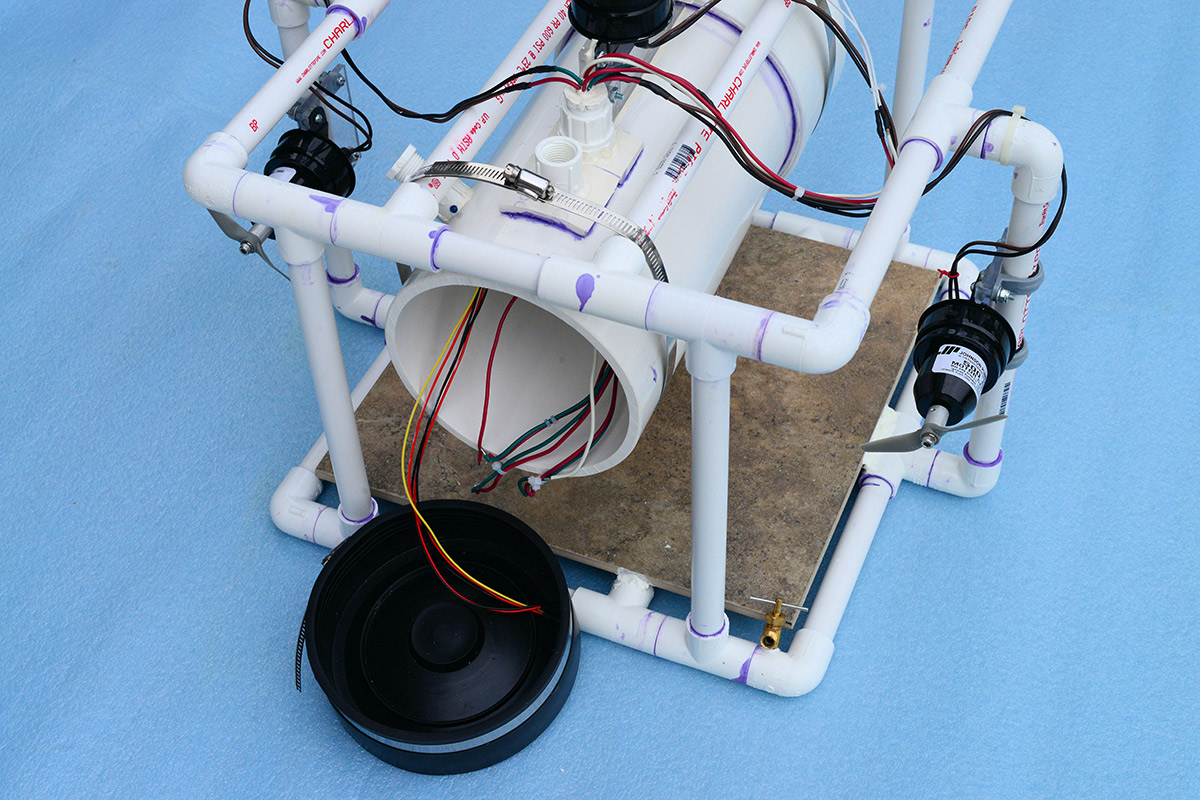

FIGURE two. The PVC frame with the electronics parcel removed.

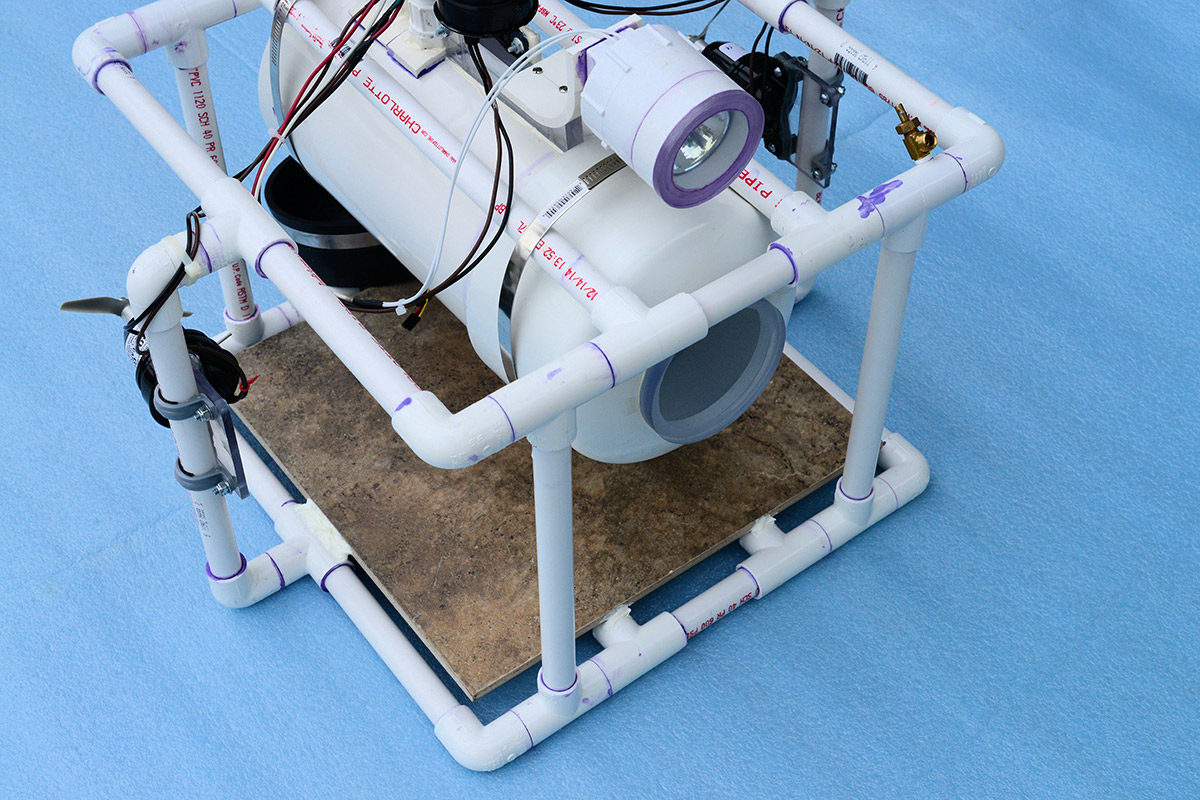

Iii 500 gallon/hour bilge pump replacement motors are used to drive the ROV. A right and left motor facing forward provide frontwards, opposite, left, and correct movement. A single vertically mounted motor on height of the six inch PVC pipe allows upwards and down motility. The motors are driven by H-bridge motor drivers capable of treatment the college current needed past the motors.

Iv inch model airplane propellers were fastened to the motor shafts. The couplers to attach the propellers to the motors were made from 1/2 inch aluminum rod with a hole drilled to fit the motor shaft, and are held in place with a fix screw on the side. The propellers were attached to the other end of the coupler by an Allen head spiral that goes into a threaded hole on the face of the rod. These can be made using a pocket-sized drill press, but I used a minor metallic lathe to eye the shaft and screw holes. Model boat propellers would probably have been a better choice, and the custom couplings would not take been necessary. The model aeroplane propellers were available, and they seem to piece of work well.

The bilge pump motors are 12 volt and rated at 2.five amps maximum. However, that rating is for running them equally a bilge pump with the manufacturer's pump impeller. Afterward attaching a 4 inch propeller to one of the motors, it was tested by running it in a five gallon pail of water. Information technology drew six amps from a 12 volt atomic number 82 acid battery considering of the load the propeller creates. This is something to remember when choosing a motor driver.

In add-on, these motors cannot exist run continuously at this higher current. For the virtually part, the motors are not run at full ability, and are turned on and off continuously while the ROV is steered. The submersion of the motors in water does assist to dissipate some heat, but it needs to be remembered that the motors are beingness overloaded at full voltage and can overheat.

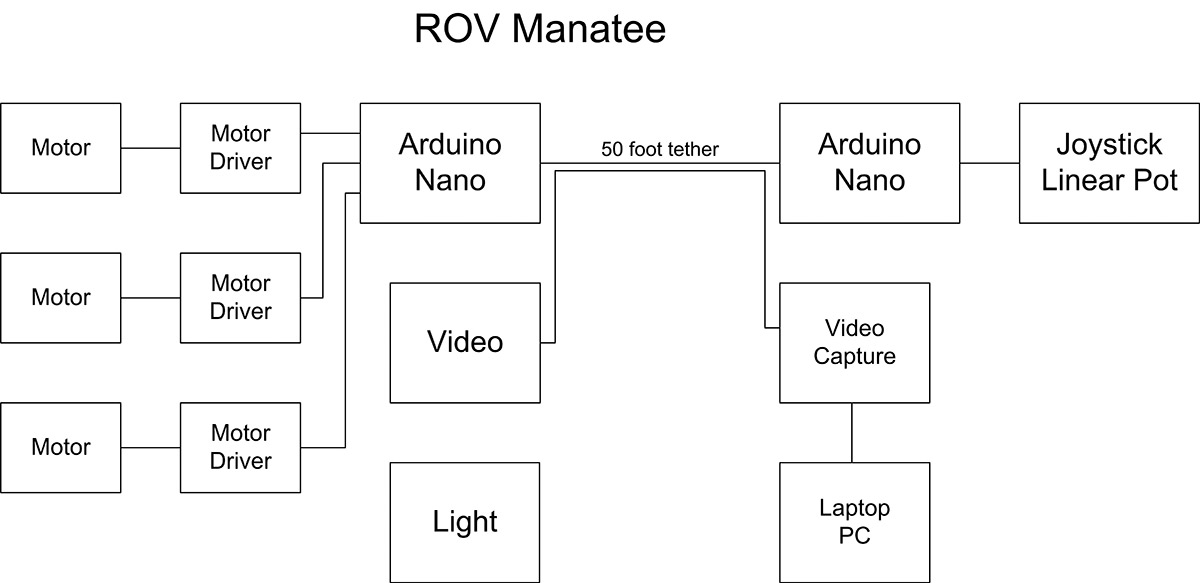

The Process for Decision-making the Motors

Two Arduino Nano microcontrollers are used for control: one topside to read the joysticks and one in the 6 inch PVC tube that houses the underwater electronics. A pocket-sized game controller type joystick mounted in a plastic box was selected to control the speed and direction of the left and right motors. A linear potentiometer was used to control the upwards/downwardly motor with center position being the motor off, and the up or downwards distance from center selects the management and power for the motor. The Arduino Nano reads the joystick and linear potentiometer, and and then — based on their positions — generates commands which information technology sends to the Nano in the ROV.

FIGURE 1. Block diagram of the basic electronics.

The commands for the motors consist of three letters followed past the iii digits of an viii-bit number which is the PWM (Pulse Width Modulation) value. They are:

- LMF255 — Left motor forward and PWM value

- LMR255 — Left motor reverse and PWM value

- RMF255 — Right motor forward and PWM value

- RMR255 — Right motor reverse and PWM value

- UMU255 — Up/downward motor up and PWM value

- UMD255 — Up/downwards motor down and PWM value

And so, a command like LMF000 volition turn the left motor off; LMF128 will run the left motor forwards at half power; and LMR255 volition run the left motor in contrary at full power. The forrard/reverse and left/right values read from the joystick are run through a unproblematic wheelchair algorithm which smoothes out the power changes as the joystick is moved.

These half-dozen-character commands are sent over 2 Arduino digital pins using the SoftwareSerial library. Assigned transmit and receive pins on the Arduino are hardwired through the tether to their opposites on the second Arduino. The ROV Arduino receives the six-character command and enables the specified motor and sets the PWM, which is so fed to the motor driver. The motor driver acts as a slave and powers the appropriate motor.

The circuitry in the ROV tin can too send data support the tether to be viewed. Given that at that place is a large battery in the ROV running the motors, information technology is useful to exist able to check on its voltage and how much charge is available. A simple two-resistor voltage divider can be read by an analog pin on the Arduino and — with a little math — converted into the bombardment voltage. Additional possible sensors are a depth gauge, compass, accelerometer, and gyroscope. Each piece of data tin be coded in a fashion similar to the commands. For example, BAT followed by battery voltage as a float, CMP followed past 359, compass bearing going clockwise, and so on.

Construction of the Frame and Main Tube

The frame is fabricated from ane/2 inch schedule 40 PVC pipe which is available in whatsoever home improvement shop. The fittings used are 12 elbows and 20 tees. The uprights that the motors are mounted on were extended outward to give more room for the propellers, simply this may have not been necessary. Additionally, the total height could have been reduced as actress room for ballast was not needed.

FIGURE three. Back of the PVC frame with safety cease cap removed.

Using ceramic tile for ballast worked very well, and the peak was peradventure not needed. In general, a cube shape of appropriate size is what works. Two brass petcocks were threaded into the 1/2 inch PVC tubes: i at the height and bottom. Opening these in the h2o allows you to very carefully trim the neutral buoyancy past adding a small amount of water into the frame.

The principal tube has a vi inch PVC cap on one stop that's attached with PVC cement. A 3-1/ii inch hole was drilled in the end of the cap, and a clear slice of one/2 inch thick Plexiglas was cemented with marine epoxy over the opening to provide a window for the video camera. The opposite end requires an end cap that tin can be removed to insert the electronics. In the past, I have tried using a six inch coupling with one cease threaded and then using a half-dozen inch threaded plug. Even with the apply of Teflon tape around the threads, at that place was still some leakage. These big threads were fabricated to accept pipe-joint compound for a tight seal, which does not work well for ease of removal. Instead, I used a half dozen inch black safe cap sealed with a metallic hose clamp; this has worked very well. The entire six inch tube is held in place underneath two ane/ii inch PVC cross pieces at the peak by two eight inch band clamps.

Figure four. Front of the PVC frame showing headlight and photographic camera window.

The elevation of the main tube has a 1/2 slice of Plexiglas vertically glued with marine epoxy for attachment of the up/downward motor, and 2 ane/ii inch PVC threaded couplings too glued in with marine epoxy to receive the PVC plugs containing the wires feeding into the tube.

A Hall-issue switch was added with a third 1/2 inch PVC threaded coupling glued into the main tube. A Hall-result switch and LED are potted into the coupling with marine epoxy. A 1/2 inch PVC plug with a Neodymium disk magnet cemented into information technology acts as the switch. When the plug is screwed into the coupling, information technology triggers a 12 volt 20 amp relay inside the master tube, activating the 12 volt circuitry. The relay contacts are wired in parallel with the main power switch. This allows ability to exist turned on and off without having to open the main tube. This excursion continuously draws most eight milliamps of current from the battery, which is non a problem for a 15 amp-hour battery.

FIGURE 5. The Hall-outcome switch and LED, with plug and attached magnet.

That's all for this installment. Adjacent time, we will comprehend the electronics parcel that reads the joystick and linear potentiometer, and so controls our motors. SV

Parts Listing

| Item | Description |

|---|---|

| A1 | Adafruit 9-DOF (Optional) |

| B1 | 12V 15AH |

| B2 | 9V Bombardment |

| BTS7960B | Motor Driver (3) |

| C1 | 1,000 µF, 16V |

| C2 | 2,700 µF, 6.3V |

| D1 | Blueish LED |

| F1 | 18A Mini Circuit Breaker or Fuse |

| FL | Flood Lamp (Optional) |

| H1 | Hall-outcome Switch 3144 |

| J1 | Three-pin Header |

| J2 | Three-pin Header |

| J3 | Three-pin Header |

| J4 | Four-pin Header |

| M1 | Left Motor, Johnson Pump 500 GPH |

| M2 | Correct Motor, Johnson Pump 500 GPH |

| M3 | Upwardly/Downwards Motor, Johnson Pump 500 GPH |

| P1 | Header Socket |

| P2 | Header Socket |

| Q1 | TIP127 PNP Darlington Transistor |

| R1 | viii.2K 1/4W Resistor |

| R2 | 4.7K one/4W Resistor |

| R3 | 1K ane/4W Resistor |

| R4 | 1K 1/4W Resistor |

| R5 | 5K 1/4W Resistor |

| R6 | 5K 1/4W Resistor |

| R7 | 20K 1/4W Linear Potentiometer |

| R8 | iv.7K ane/4W Resistor |

| R9 | 8.2K 1/4W Resistor |

| R10 | 4.7K one/4W Resistor |

| Relay | 12V 20A Contacts |

| Switch | 20A Contacts |

| Switch | Mini Toggle |

| U1 | Arduino Nano |

| U2 | Arduino Nano |

| U3 | LM7805 5V Regulator |

| Video Photographic camera | NTSC |

| Miscellaneous 1/2 inch PVC Piping one/2 inch PVC Elbows one/2 inch PVC Tees 1/2 inch PVC Threaded Couplings 1/2 inch PVC Threaded Plugs Six inch PVC Pipe Six inch PVC Pipe Cap Six inch Prophylactic End Cap, with Band Clamp i/four and ane/ii inch Plexiglas PVC Cement Marine Epoxy Silicon Cement Eight inch Band Clamps Nylon Cable Ties Various Screws, Basics Hookup Wire Cat5 Cable, 50 feet Petcock Valves (2) Ceramic Tile | |

Downloads

201603-Wierenga.nothing

What's in the null?

Express PCB schematic and PCB files

Arduino Code Files

How Do I Calculate How Much Ballast I Need Add To A Rov To Reach Neutral Buoyancy?,

Source: https://www.servomagazine.com/magazine/article/march2016_UnderwaterROV

Posted by: boltonhicing.blogspot.com

0 Response to "How Do I Calculate How Much Ballast I Need Add To A Rov To Reach Neutral Buoyancy?"

Post a Comment